5 Ways to Maximize Efficiency in DTF Transfer Processes

In the world of printing, DTF (Direct to Film) transfer processes have gained significant popularity due to their versatility and high-quality results. Whether you are a small print shop or a large-scale operation, maximizing efficiency in DTF transfer processes should be a top priority to save time and increase productivity. Here are five effective ways to achieve this:

1. Invest in High-Quality Equipment

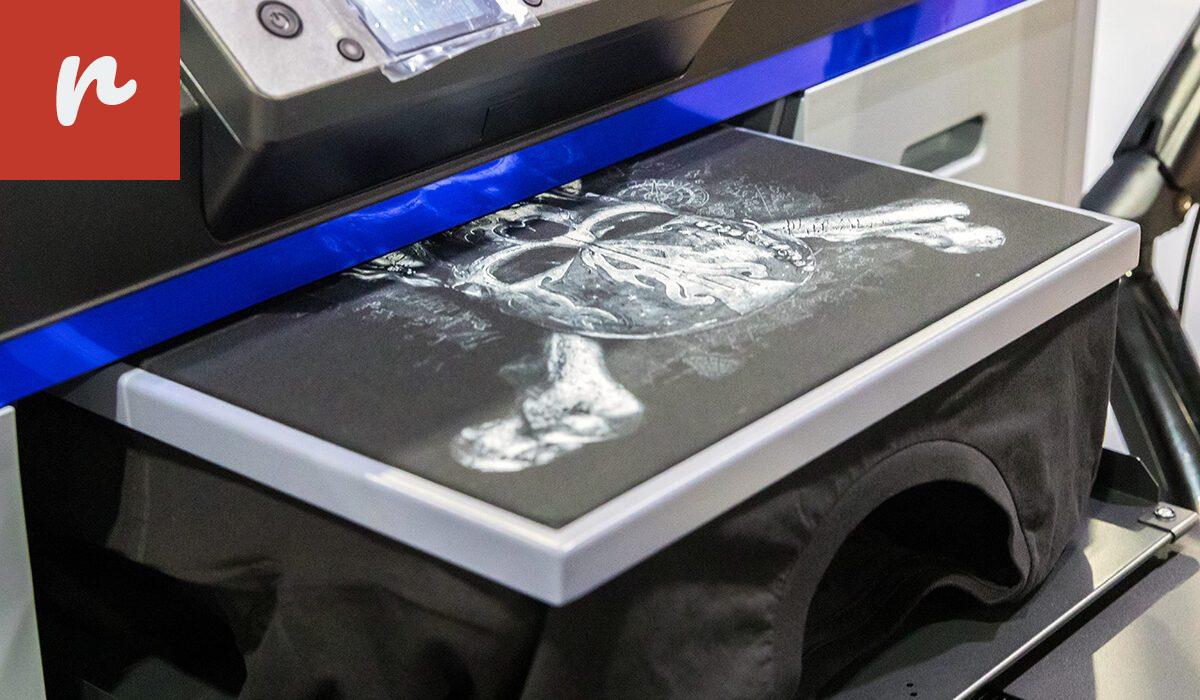

One of the key factors that can amplify efficiency in DTF transfer processes is investing in high-quality equipment. Opt for printers and heat presses that are specifically designed for DTF transfers. These machines will not only provide better print quality but also ensure smoother operations, reduced downtime, and improved overall productivity.

2. Streamline Workflow

Streamlining your workflow is crucial for achieving maximum efficiency. Analyze your current processes to identify any bottlenecks or areas where time is wasted. Consider implementing automation technologies wherever possible, such as using software to streamline file preparation or using robotics for material handling. By reducing manual intervention and optimizing your workflow, you can significantly increase efficiency.

3. Maintain Proper Inventory Management

Keeping track of your inventory is essential to avoid delays and interruptions in DTF transfer processes. Maintain a proper inventory management system to ensure you have an adequate stock of films, inks, and other necessary supplies. Regularly monitor and replenish your inventory to prevent any unexpected hold-ups during production and keep the process flowing smoothly.

4. Optimize File Preparation

Efficient file preparation is critical to avoid wastage of time and resources. Make sure all the digital files are properly formatted and optimized for DTF transfers. Utilize software tools that can automatically convert and optimize your design files for DTF printing, reducing the need for manual adjustments and minimizing errors. This optimization will streamline the printing process and enhance overall efficiency.

5. Create a Well-Organized Workspace

An organized workspace can make a significant difference in your DTF transfer processes. Ensure that your work area is clean, well-maintained, and properly organized. Have clear labeling and storage systems to easily locate and access the required materials. This organization will help reduce the time spent searching for supplies and improve overall efficiency.

In conclusion, optimizing efficiency in DTF transfer processes can greatly benefit your print business. By investing in quality equipment, streamlining your workflow, managing inventory effectively, optimizing file preparation, and maintaining a well-organized workspace, you can maximize productivity and achieve better results. Implement these five strategies and witness the positive impact on your DTF transfer processes.

The Benefits of Maximizing Efficiency in DTF Transfer Processes

When it comes to the transfer of DTF (Direct to Fabric) images, maximizing efficiency is crucial. Efficiency in the DTF transfer process can lead to a range of benefits for businesses, including time and cost savings, increased productivity, and improved customer satisfaction.

One of the key advantages of maximizing efficiency in DTF transfer processes is the time-saving aspect. By optimizing the workflow, businesses can reduce the time required to transfer images onto fabric. This means faster turnaround times for customers, which can improve overall customer satisfaction and increase the likelihood of repeat business.

Furthermore, by maximizing efficiency, businesses can also reduce costs associated with the DTF transfer process. Streamlining workflows and eliminating unnecessary steps or redundancies can help minimize wastage of resources and materials. This can have a significant impact on the bottom line, making the business more profitable.

- List item 1: Improved productivity

- List item 2: Enhanced quality

Another benefit of maximizing efficiency in DTF transfer processes is increased productivity. When workflows are optimized, tasks can be completed more quickly and smoothly. This results in higher output and productivity levels within the business. By utilizing time-saving techniques and technologies, the entire process becomes more streamlined and efficient.

Efficiency improvements can also contribute to better quality output. With optimized workflows, businesses can reduce the chances of errors or mistakes during the transfer process. This ensures that the final product meets the desired quality standards, resulting in satisfied customers and a positive reputation for the business.

In conclusion, maximizing efficiency in DTF transfer processes brings numerous benefits to businesses. It saves time, reduces costs, improves productivity, and enhances the quality of the output. By focusing on efficiency, businesses can optimize their operations and gain a competitive edge in the marketplace. So, if you are involved in DTF transfers, make sure to prioritize efficiency to unlock these benefits.

Efficiency Hacks for Optimizing DTF Transfer Processes

When it comes to transferring direct-to-fabric (DTF) prints onto garments, efficiency is key. You want to streamline your DTF transfer processes to save time and increase productivity. In this article, we will explore some efficiency hacks that can help you optimize your DTF transfer processes.

1. Prepare Your Workflow: Before you begin the DTF transfer process, it's essential to have a well-organized workflow. Make sure you have all the necessary materials and equipment readily available. This includes your DTF printer, transfer film, heat press machine, and garments. Having everything in place will help you avoid unnecessary delays and interruptions.

2. Use High-Quality DTF Films: The quality of your DTF films plays a crucial role in the success of your transfers. Invest in high-quality films that offer excellent adhesion and color vibrancy. High-quality films are also more durable and will withstand multiple washes without fading or cracking.

3. Optimize Image Resolution: To ensure crisp and clear DTF transfers, it's important to optimize your image resolution. Use high-resolution images with a minimum of 300 dpi (dots per inch). This will help maintain the clarity and detail of your prints, resulting in professional-looking garments.

- 4. Prewash Garments: Before transferring the design onto the fabric, it's recommended to prewash the garments. This helps remove any residual chemicals or dirt that may interfere with the adhesion of the transfer film. Prewashing also allows the fabric to shrink if necessary, preventing any distortions or misalignment during the transfer process.

- 5. Maintain Proper Heat Press Temperature and Time: The heat press machine plays a significant role in the DTF transfer process. Make sure to set the correct temperature and time for your specific transfer film and garment material. Refer to the manufacturer's instructions for the optimal settings. Failure to maintain the right temperature and time can result in poor adhesion or scorching of the fabric.

6. Test Before Full Production: Before diving into mass production, it's wise to test your DTF transfer process on a sample garment. This allows you to fine-tune the settings, troubleshoot any issues, and ensure the desired outcome. Testing helps you avoid costly mistakes and saves time in the long run.

7. Properly Store Transfer Films: To ensure the longevity and quality of your transfer films, it's crucial to store them properly. Keep them in a cool, dry place, away from direct sunlight and excessive humidity. Improper storage can cause the films to deteriorate, affecting their effectiveness and adhesion properties.

In conclusion, optimizing your DTF transfer processes can significantly enhance efficiency and productivity. By following these efficiency hacks, you can streamline your workflow, improve the quality of your transfers, and save time and resources. Implement these strategies and watch your DTF transfer processes become smoother and more successful.

Improving Productivity: How to Maximize Efficiency in DTF Transfer Processes

Productivity plays a crucial role in any business, and finding ways to maximize efficiency is key to success. In the world of textile printing, one process that requires careful attention is DTF (Direct to Film) transfer. DTF is a popular method for transferring designs onto various fabric types. To ensure smooth and efficient DTF transfer processes, follow these tips:

1. Quality Design Preparation: Before transferring any design, it is important to ensure that it is of high quality. Use a professional graphic design software to create or edit your design. Pay attention to details such as resolution, color accuracy, and size. A well-prepared design will result in better transfer quality and less wastage.

2. Proper Equipment Maintenance: Regular maintenance of your DTF transfer equipment is essential to prevent downtime and ensure consistent quality. Clean your printer heads regularly, check for any clogging, and replace parts as needed. Keep your equipment in good working condition to avoid unexpected issues during the transfer process.

3. Material Selection: The choice of materials for DTF transfer can greatly affect the end result. Opt for high-quality films and transfer papers specifically designed for DTF printing. These materials adhere better to fabrics and produce vibrant, long-lasting prints. Using subpar materials may result in poor transfer quality and reduced productivity.

- 4. Efficient Workflow: Streamlining the workflow is crucial to maintaining a productive DTF transfer process. Analyze your current workflow and identify any bottlenecks or redundant steps. Look for opportunities to automate tasks or introduce better tools. For example, using a dedicated software for color management can expedite the color matching process and save valuable time.

- 5. Proper Training: Ensuring that your employees are properly trained in DTF transfer processes is essential for maximizing efficiency. Conduct regular training sessions to update their knowledge and skills. Provide clear guidelines and standard operating procedures to minimize errors and reduce reworks. Well-trained employees will be more confident and competent in their tasks, leading to improved productivity.

6. Continuous Improvement: Don't be afraid to experiment and try new techniques or technologies to enhance your DTF transfer processes. Keep up with industry trends and stay informed about new methods or equipment that can help boost efficiency. Regularly evaluate your processes and seek feedback from employees and customers to identify areas for improvement.

By implementing these tips, you can significantly improve productivity and efficiency in your DTF transfer processes. Remember, a well-prepared design, proper equipment maintenance, good material selection, efficient workflow, proper training, and continuous improvement are the keys to success in maximizing efficiency in DTF transfers.

Maximizing Efficiency in DTF Transfer Processes is crucial for businesses looking to streamline their production workflows and optimize their output. Implementing effective strategies and utilizing advanced technologies can greatly enhance productivity and eliminate unnecessary bottlenecks. By employing the right tools and techniques, such as automated systems and precision equipment, companies can significantly reduce the time and effort required for DTF printing. To learn more about how to become an Efficiency Maximizer in the DTF transfer industry, visit dtfintexas.com.

The Ultimate Guide to Maximizing Efficiency in DTF Transfer Processes

In the world of printing, DTF (Direct to Film) transfer processes have gained significant popularity due to their efficiency and quality. Whether you are a printing business owner or an enthusiast, maximizing efficiency in DTF transfer processes is crucial to ensure productivity and cost-effectiveness. In this guide, we will discuss various strategies and tips to help you achieve optimal efficiency in DTF transfer processes.

1. Invest in High-Quality DTF Equipment: The first step towards maximizing efficiency in DTF transfer processes is to invest in high-quality DTF equipment. High-quality machines and materials will ensure consistent and accurate transfers, reducing the chances of reprints and wastage.

2. Streamline Your Workflow: Developing a streamlined workflow is essential for efficient DTF transfer processes. Organize your space, establish a logical sequence of tasks, and set up clear guidelines for each step in the process to minimize errors and save time.

- List item 1: Designate specific areas for prepping, printing, and post-processing.

- List item 2: Create a checklist to ensure all necessary materials are readily available.

3. Implement Quality Control Measures: To avoid costly mistakes and reworks, implement rigorous quality control measures throughout the DTF transfer process. Regularly inspect the equipment, materials, and final prints to identify any issues and make necessary adjustments.

4. Optimize File and Print Preparation: Proper file and print preparation can significantly enhance efficiency in DTF transfer processes. Ensure your design files are optimized for printing, removing unnecessary elements and reducing file sizes. Additionally, calibrate your printer settings to achieve optimal color accuracy and vibrancy.

5. Maintain Equipment and Materials: Regular maintenance of your DTF equipment is vital to keep it functioning smoothly. Clean the printer heads regularly, check for any clogged nozzles, and replace worn or damaged parts promptly. Moreover, stock up on high-quality materials like DTF films and ink to avoid delays and subpar prints.

6. Train Your Staff: Adequate training and clear instructions are essential for efficient DTF transfer processes. Ensure your staff is well-trained on the use of DTF equipment, file preparation, and troubleshooting common issues. This will reduce errors, save time, and minimize the need for supervision.

7. Embrace Automation: Take advantage of technology and embrace automation to enhance efficiency. Explore software solutions that automate repetitive tasks like color separation and file preparation. This will free up your time for more critical aspects of the DTF transfer process.

8. Stay Updated with Industry Trends: Remaining up-to-date with the latest advancements and trends in DTF transfer processes is crucial for maximizing efficiency. Attend industry events, read relevant publications, and engage with professionals to stay informed about new techniques, materials, and equipment that can improve your workflow.

In Conclusion: Maximizing efficiency in DTF transfer processes requires careful planning, investing in quality equipment, optimizing workflows, and continuous improvement. By following the tips and strategies mentioned in this guide, you can streamline your DTF transfer processes, reduce costs, and deliver high-quality prints consistently.

Dec 26, 2023 says :

Enhancing Independence With Richardson Home Health Care